SAE 8620 ALLOY STEEL | SAE 8620H

SAE 8620/AISI 8620 alloy steel manufacturers and suppliers, supplied with round rods,square/flat bars,rollers,shafts,blocks and forging pieces.

SAE 8620 Alloy Steel is a low nickel,chromium-molybdenum alloy steel as per American standard. SAE 8620 steel gives good core strength and toughness when carburised, hardened and tempered.

Typical uses for SAE 8620 steel include Arbors, Bearings, Bushings, Cam Shafts, Guide pins, Piston pins, Splined shafts, Ratchets, Sleeves etc.

| Chemical Composition | |||||||||

|

National Standard |

Grade | C | Si | Mn | Cr | Mo | Ni | P | S |

| DIN |

20NiCrMo2-2 (1.6523) |

0.17-0.23 | ≤0.4 | 0.65-0.85 | 0.35-0.7 | 0.15-0.25 | 0.4-0.7 | ≤0.025 | ≤0.035 |

| SAE | 8620 | 0.18-0.23 | 0.15-0.35 | 0.7-0.9 | 0.4-0.6 | 0.15-0.25 | 0.4-0.7 | ≤0.035 | ≤0.04 |

| JIS | SNCM220 | 0.17-0.23 | 0.15-0.35 | 0.6-0.9 | 0.4-0.65 | 0.15-0.3 | 0.4-0.7 | ≤0.035 | ≤0.04 |

| GB | 20CrNiMoA | 0.18-0.23 | 0.15-0.35 | 0.7-0.9 | 0.4-0.6 | 0.2-0.3 | 0.4-0.7 | ≤0.035 | ≤0.04 |

What is the Difference between SAE 8620 and SAE 8620H?

In fact, there is little difference in composition between SAE 8620 and SAE 8620H.

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| 8620H | 0.17-0.23 | 0.15-0.35 | 0.60-0.95 | ≤0.035 | ≤0.04 | 0.35-0.65 | 0.35-0.75 | 0.15-0.25 |

However, the letter H is added after SAE 8620, which means that the material has requirements for hardenability.SAE 8620H steel, as a Cr-Ni-Mo alloy carburized steel, is widely used as a material for impact-resistant and wear-resistant parts such as automobile bearings and gears.

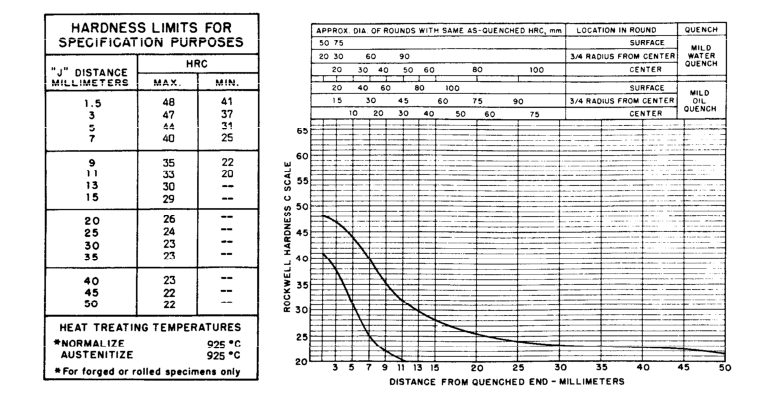

8620H Hardenability Curve

What are macroscopic structure requirements for SAE 8620 steel?

The macroscopic structure defects are observed under low-power magnification,mainly affects the compactness of the material, which in turn has a great influence on the processability and mechanical properties of the steel.For SAE 8620 steel, the macroscopic structure must meet the following requirements

| SAE 8620 steel quality classification | General Porosity(Grade) | Central Porosity(Grade) | Pattern Segregation(Grade) |

General Spot Segregation(Grade) |

| Quality steel | ≤3.0 | ≤3.0 | ≤3.0 | ≤1.0 |

| High quality steel | ≤2.0 | ≤2.0 | ≤2.0 |

not allowed |

| Premium quality steel | ≤1.0 | ≤1.0 | ≤1.0 |

not allowed |

What are non-metallic inclusion requirements for SAE 8620 steel?

Non-metallic inclusions in SAE 8620 steel will disrupt the internal continuity of the material, also affect the purity of the material, and ultimately lead to a decrease in the toughness and plasticity of the material.For SAE 8620 steel, the non-metallic inclusions must meet the following requirements

| SAE 8620 steel quality classification | A | B | C | D | ||||

| Fine | Coarse | Fine | Coarse | Fine | Coarse | Fine | Coarse | |

| High quality steel | ≤3.0 | ≤2.5 | ≤3.0 |

≤2.0 |

≤2.0 |

≤1.5 |

≤2.0 |

≤1.5 |

| Premium quality steel | ≤2.5 | ≤2.0 | ≤2.5 | ≤1.5 | ≤1.5 | ≤1.0 | ≤1.5 | ≤1.0 |

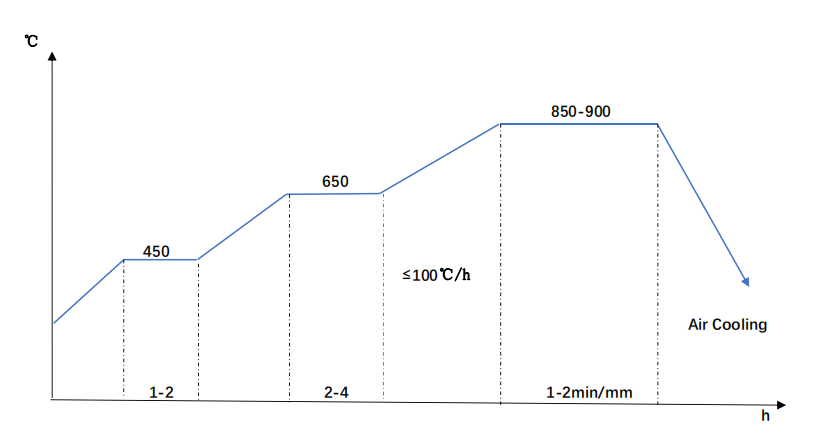

Heat Treatment For SAE 8620

- Normalizing

SAE 8620 steel is usually formed by hot working.The high temperature state makes the grains of the material coarse and the structure is uneven. In order to obtain a refined and uniform structure of the material and prepare for the subsequent carburizing process, normalizing heat treatment is required.

Process Details:

- Normalizing temperature:850-900°C

- Evenly heats and maintains temperature in three steps

- Cooling in the air

- Hardness: 143-196HBW

SAE 8620 Steel Normalizing Diagram

- Annealing

SAE 8620 steel is normally delivered in the annealed condition. And its annealing is divided into the following according to the purpose

- Complete annealing (recrystallization annealing):800-860°C

- Isothermal annealing:660°C,keep temperature for 4 hours,hardness below 187HBW.

- Dehydrogenation annealing:650°C

Cooling Method:Furnace Cooling

SAE 8620 Steel Mechanical Properties in Normalized & Annealed condition

| Tensile Strength | Yield Strength | Elongation | Reduction of Area | Impact Charpy-V |

Hardness |

|

| Normalized | 635 Mpa | 355 Mpa | 26.3% | 60% | 100 J | 183 HBW |

| Annealed | 535 Mpa | 385 Mpa | 31.3% | 62% | 112 J | 149 HBW |

- Heat Treatment Process of SAE 8620 Carburized Steel

Preliminary heat treatment:

- Normalizing at 900°C

- Tempering at 650°C

- Hardness below 229HBW

Carburizing temperature:900-920°C

Quenching temperature:780-800°C,oil quench

Tempering temperatre:150-170°C

Surface hardness:59-63HRC

Core hardness: above 30HRC

Effective carburizing layer depth: 1.4-1.8mm

Mechanical Property( for reference only)

1.Tensile strength: ≥980MPa

2.Yield point:≥785MPa

3.Percentage reduction of area after fracture: ≥40%

4.Elongation after fracture: ≥9%

5.Impact test (+20°C): 47J

Delivery Condition

1.Shape:Round/Square / Flat/Shafts/Rollers/Blocks

2.Surface condition:Black surface/Bright surface

3.Heat Treatment:Normalized/Annealed/QT

4.Straightness:Max 3mm/m(Enhanced straightness may be available on request)

5.Length:3000-5800mm suitable for 20″container. above 6000mm,suitable for 40″ container

6.Grain Size: 5-8 acc to ASTM E112-96

7.Ultrasonic Standard: Sep1921/ASTM A388/EN 10228-3

8.Non Metallic Inclusion: 2 max acc to ASTM E45 /K4≤20 acc to DIN 50602

9.Forging Ratio: minimum 4 : 1

10.Marking: Grade/Weight/Length/Size/Heat Number

Quality Certification

A material test report(Inspection Certificate EN 10204 3.1) will be provided, documenting the following:

1.Chemical analysis

2.Mechanical properties

3.Surface hardness

4.Non Metallic Inclusion

5.Heat Treatment Process

6.Grain size

7.Forging ratio

8.Ultrasonic test report

Supply Size & Condition For SAE 8620

- Round Bars: Dia.80 – 1,000mm as Forged

- Flat / Square Bars: Thickness Max.800mm

- Shafts, Rollers, Blocks: Customized or According to Drawing

- Rolled Round Bars: Dia.16 – 250mm with UT Assurance

Heat treatment:Quenched and Tempered (+QT), Normalizing (+N), Annealing (+A)

Surface finish:Black / Rough turned / Peeled