DIN 1.2311 TOOL STEEL |40CRMNMO7 | P20 ROUND BAR

DIN 1.2311 Tool Steel is a low alloyed steel with 2.0% Cr ,0.15%Mo as per DIN standard.As plastic mold tool steel, it has good toughness,wear resistance after Nitriding. It is mostly used in the hardened and tempered condition with hardness 285-320 HBW.

Typical application for this steel are:For large injection and compression molds, Blow molds,die holder, backers and Structural components, shafts,etc.

1.DIN 1.2311 steel Supply Form & Size

| Form of Supply | Size(mm) | Length(mm) |

| Round bar | Φ6-Φ1,000 | 3,000-10,000 |

| Square bar | 100x100-600x600 | 3,000-6,000 |

| Plate/Sheet |

Thickness :20-400 Width:80-1,000 |

2,000-6,000 |

| Flat bar/Blcoks |

Thickness :120-800 Width:120-1,500 |

2,000-6,000 |

2.Surface Finish&Tolerance

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

3.Chemical Composition

| Grade | C | Si | Mn | P | S | Cr | Mo |

| 1.2311 | 0.35-0.45 | 0.2-0.4 | 1.3-1.6 | ≤ 0.03 | ≤ 0.03 | 1.8-2.1 |

0.15-0.25 |

| P20 | 0.28-0.4 | 0.2-0.8 | 0.6-1.0 | ≤ 0.03 | ≤ 0.03 | 1.4-2.0 | 0.3-0.55 |

4.Related Specifications

ASTM:P20

DIN:40CrMnMo7

AFNOR:40CMD8

GB:3Cr2Mo

5.Heat Treatment & Mechanical Property

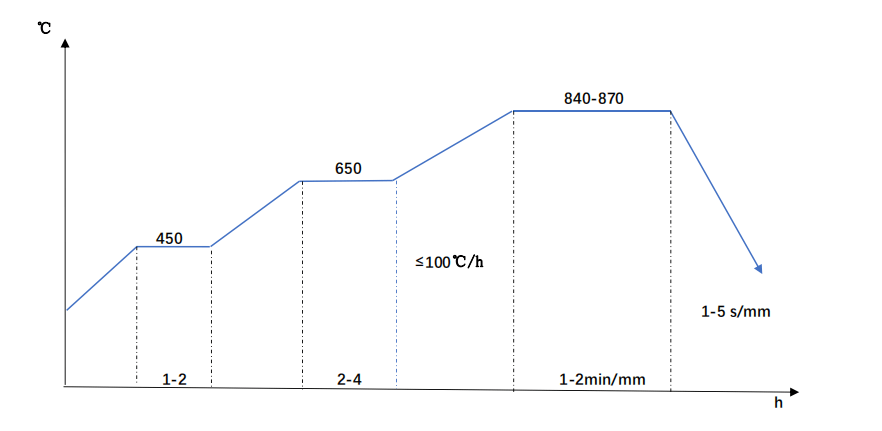

Quenching Details

1.Quench temperature:840-870℃

2.Three steps for heating,hold suitable time for the steel to be thoroughly heated.

3.Oil or water quench.

4.Tempering immediately after quenched

DIN 1.2311 Quenching Diagram

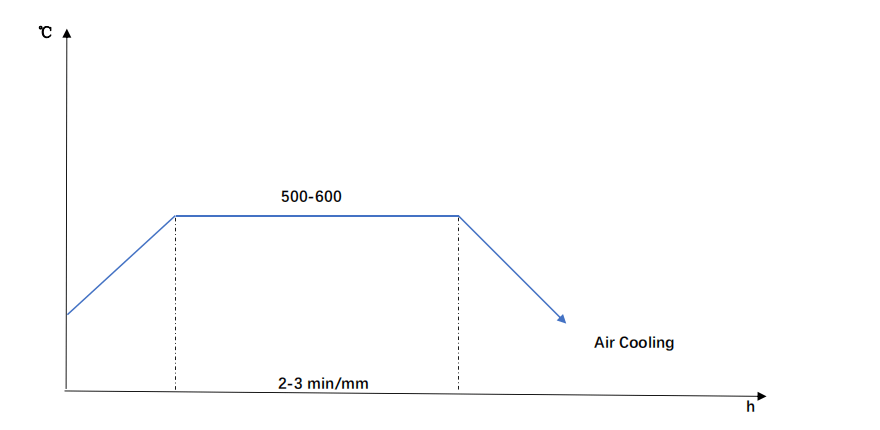

Tempering Details

1.Temper temperature:500-600℃

2.Air cooling.

DIN 1.2311 Tempering Diagram

DIN 1.2311 Mechanical Property With Quenching and Tempering condition

| Size mm |

Tensile,Mpa |

Yield,Mpa |

Charpy Impact,J |

Hardness,HB |

| 355*500 | 1000 | 900 | 20 | 290-327 |

| 400*450 | 1100 | 910 | 25 | 302-330 |

| 500*1000 | 1100 | 935 | 24 | 292-330 |

DIN 1.2311 Hardness Vs Tempering temperature

| Tempering Temperature,℃ | 200 | 300 | 400 | 500 | 600 | 700 |

| Hardness,HRC | 50 | 48 | 46 | 42 | 36 | 28 |

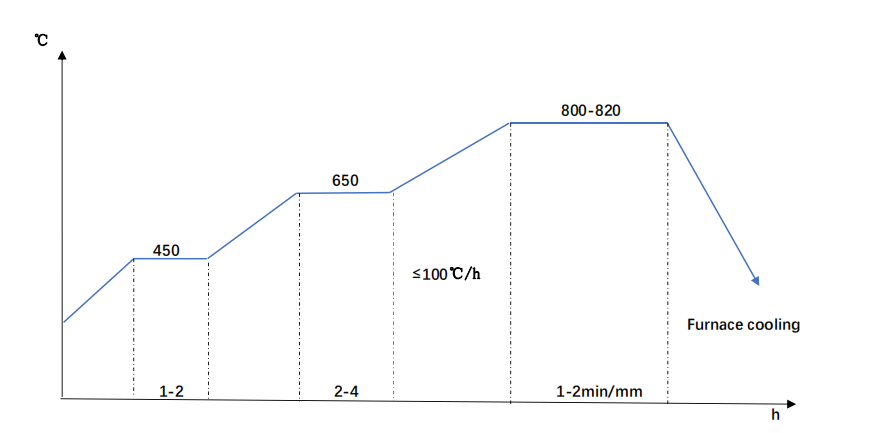

Annealing Details

1.Annealing temperature:800-820℃

2.Enough soaking time for the steel heating

3.Cooling in the furnace.

4.Max hardness:229HB

DIN 1.2311 Annealing Diagram