DIN 1.2714 HOT WORK TOOL STEEL | 56NICRMOV7 | L6 | SKT4

DIN 1.2714 Steel is defined as Hot work Tool Steel as per DIN 17350 Germany standard( replaced by EN ISO 4957).With Min 1.0%Cr-0.45%Mo-1.5%Ni-0.07%V alloy elements, it have high strength,high hardness and high wear-resistance.

DIN 1.2714 is generally supply in hardened, quenched & tempered condition (Hardness:370-410HBW), and also in annealed condition in special use.Due to its good performace, it is mainly used for forging dies,punches,plastic molds,and die holders etc.

1.DIN 1.2714 steel Supply Form & Size

| Form of Supply | Size(mm) | Length(mm) |

| Round bar | Φ6-Φ1,000 | 3,000-10,000 |

| Square bar | 100x100-600x600 | 3,000-6,000 |

| Plate/Sheet |

Thickness :20-400 Width:80-1,000 |

2,000-6,000 |

| Flat bar/Blcoks |

Thickness :120-800 Width:120-1,500 |

2,000-6,000 |

2.Surface Finish&Tolerance

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

3.Chemical Composition

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo | V |

|

1.2714 (56NiCrMoV7) |

0.5-0.6 | 0.1-0.4 | 0.65-0.95 | ≤ 0.03 | ≤ 0.03 | 1.0-1.2 | 1.5-1.8 |

0.45-0.55 |

0.07-0.12 |

4.Related Specifications

ASTM:L6

JIS:SKT4

GB:5CrNiMo

DIN/EN/ISO:55NiCrMoV7

5.Heat Treatment & Mechanical Property

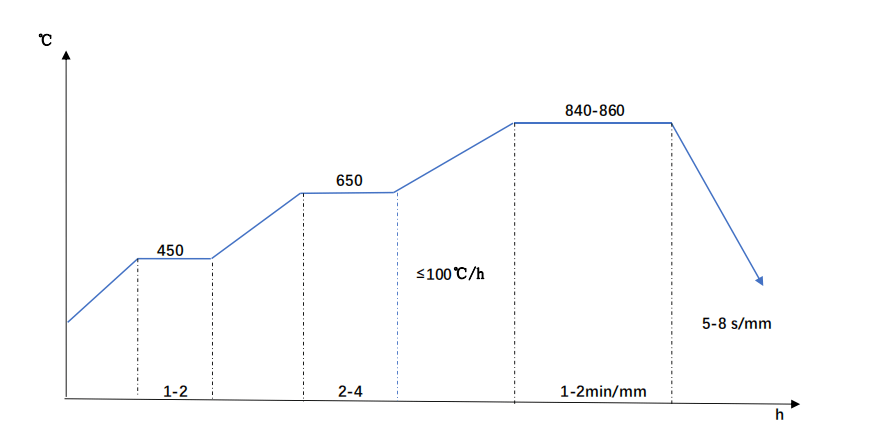

Quenching Details

1.Quench temperature:840-860℃

2.Keep suitable time for the steel to be thoroughly heated.

3.Oil or water quench.

4.Tempering immediately after quenched

DIN 1.2714 Quenching Diagram

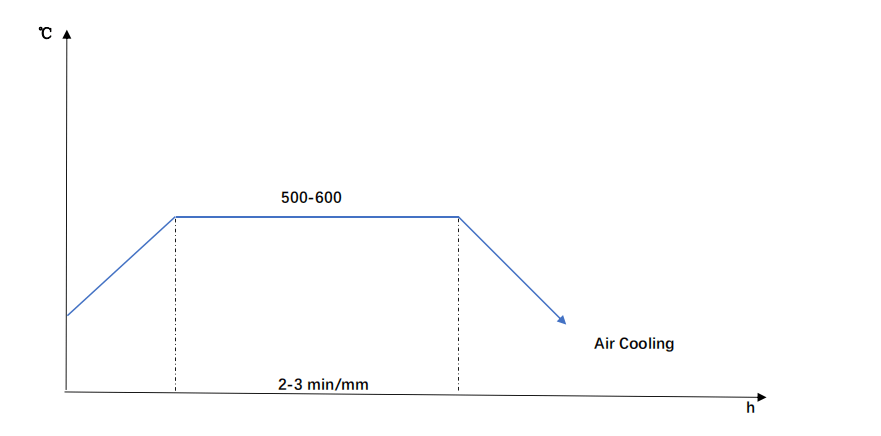

Tempering Details

1.Temper temperature:500-600℃

2.Air cooling.

DIN 1.2714 Tempering Diagram

DIN 1.2714 Hardness Vs Tempering temperature

| Tempering Temperature,℃ | 400-480 | 500-550 | 570-650 |

| Hardness,HRC | 42-46 | 38-41 | 32-36 |

DIN 1.2714 Mechanical Property With Quenching and Tempering condition

|

Size mm |

Tensile Mpa |

Yield Mpa |

Elongation % |

Reduction % |

Charpy Impact J |

Surface Hardness HB |

Core Hardness HB |

| Φ180 | 1250 | 1000 | 17 | 58.5 |

L:55/54/42 T:37/36/25 |

377-394 | 387-400 |

| Φ305 | 1280 | 1060 | 16 | 55.5 |

L:42/40/44 T:27/28/30 |

376-400 | 370-386 |

| 300*300 | 1200 | 1000 | 18 | 56.5 |

L:52/52/60 T:42/32/26 |

360-386 | 360-368 |

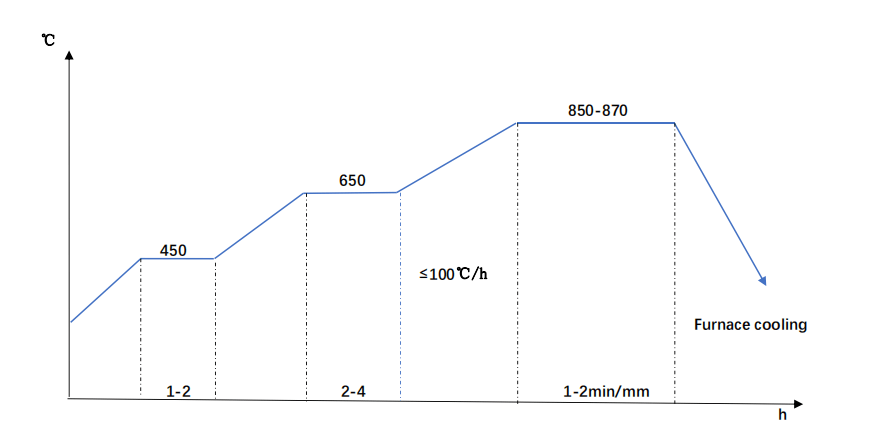

Annealing Details

1.Annealing temperature:850-870℃

2.Enough soaking time for the steel heating

3.Cooling in the furnace.

4.Max hardness:229HB

DIN 1.2714 Annealing Diagram