SAE 4340 ALLOY STEEL | AISI 4340

SAE 4340/AISI 4340 alloy steel manufacturers and suppliers, supplied with round rods,square/flat bars,rollers,shafts,blocks and forging pieces.

SAE 4340 Alloy steel is a general nickel-molybdenum alloy steel as per American standard which has high strength,toughness and excellent hardenability.

SAE 4340 steel is usually supplied under quenched and tempered condition at the hardness of 28 – 34HRC. Typical applications are for structural use, such as aircraft landing gear, power transmission gears and shafts and other structural parts.

| Chemical Composition | |||||||||

|

National Standard |

Grade | C | Si | Mn | Cr | Mo | Ni | P | S |

| DIN |

34CrNiMo6 (1.6582) |

0.30-0.38 | ≤0.40 | 0.50-0.80 | 0.9-1.2 | 0.15-0.30 | 1.30-1.70 | ≤0.025 | ≤0.035 |

| SAE | 4340 | 0.38-0.43 | 0.15-0.35 | 0.60-0.80 | 0.7-0.9 | 0.15-0.25 | 1.65-2.0 | ≤0.035 | ≤0.04 |

| JIS | SNCM447 | 0.36-0.43 | 0.15-0.35 | 0.60-0.90 | 0.6-1.0 | 0.15-0.30 | 1.60-2.0 | ≤0.035 | ≤0.04 |

| GB | 40CrNiMoA | 0.37-0.44 | 0.17-0.37 | 0.50-0.80 | 0.6-0.9 | 0.15-0.25 | 1.25-1.65 | ≤0.025 | ≤0.025 |

| BS | EN24 | 0.36-0.43 | 0.1-0.35 | 0.45-0.70 | 1.0-1.4 | 0.20-0.35 | 1.30-1.70 | ≤0.035 | ≤0.035 |

What is the Difference Between SAE 4340 and AISI 4340?

let’s make a conclusion first, there is almost no difference between SAE 4340 and AISI 4340.

SAE 4340 is from the Society of Automotive Engineers,and AISI 4340 is from the American Iron and Steel Institute.They essentially point to the same meaning of the material, which is the 4340 material in the ASTM A29 standard. It is just that the implementation of the society is different, and the statement is different.

Therefore, from the above, it can be seen that “4340”, “AISI 4340” or “SAE 4340”, although written differently, but in most general industrial applications,any of the above is considered equivalent.

SAE 4340 Steel Physical Property

| Density, g/cm3 | 7.87 |

| Melting point,℃ | 1408 |

| Specific heat capacity,(0~100℃),J/(kg.k) | 582(200℃) |

| Linear expansion coefficient,10^-6/k | 0~100℃ |

| 12.8 | |

| Poisson's ratio | 0.295 |

| Elastic Modulus,Mpa | 213000 |

| Shear modulus,Mpa | 82300 |

| Resistivity,10^-8 Ω.m | 36.2(150℃) |

| Thermal conductivity,W/(m.K) | 36.01(150℃) |

Critical Temperature for Heat Treatment of SAE 4340

- Ac1:732℃

- Ac3:774℃

- Ar1:680℃

Heat Treatment For SAE 4340

- Normalizing & Annealing For SAE 4340

Normalizing and annealing heat treatments have completely different effects on SAE 4340 steel, and the heat treatment processes are also different.

For the normalizing of SAE 4340, it is rarely used in actual production. Its main purpose is to optimize the structure and prepare the structure for the final quenching and tempering heat treatment.

While for the annealing of SAE 4340 steel,the methods are diversified.Common annealing methods are generally divided into the following types.

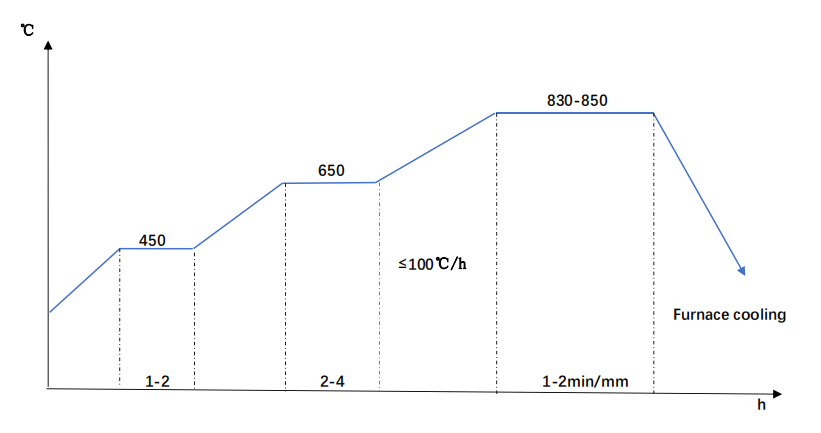

- Complete annealing (recrystallization annealing):830-850°C

- Isothermal annealing:650°C,keep temperature for 8 hours

- Soft annealing: 670-700°C

- Stress relief annealing:600-650°C

Cooling Method:Furnace Cooling

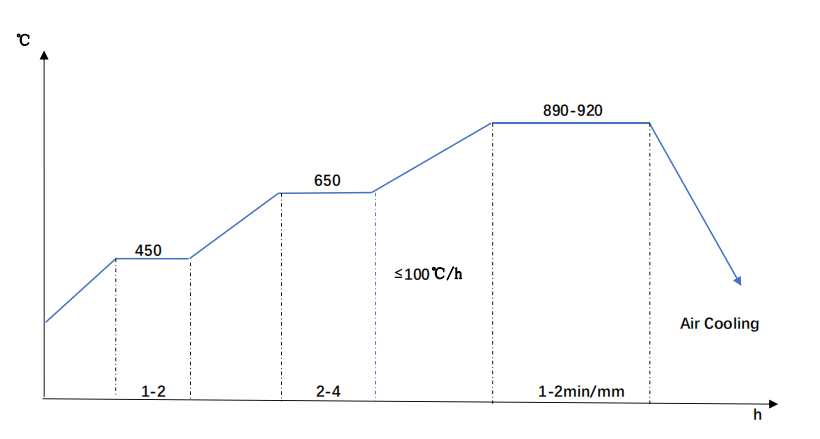

SAE 4340 Steel Normalizing Diagram

SAE 4340 Steel Annealing Diagram

SAE 4340 Steel Mechanical Properties in Normalized & Annealed condition

| Tensile Strength | Yield Strength | Elongation | Reduction of Area | Impact Charpy-V |

Hardness |

|

| Normalized | 1280 Mpa | 860 Mpa | 12.2% | 36% | 16 J | 363 HBW |

| Annealed | 745 Mpa | 470 Mpa | 22% | 50% | 51 J | 217 HBW |

- Quenching & Tempering(QT) For SAE 4340

For Cr-Ni-Mo series alloy steel like SAE 4340 steel,it is more suitable for quenching and tempering heat treatment than Cr-Mo series alloy steel, such as 4140, 4130, etc.After quenching and tempering, SAE 4340 steel can obtain high strength and high hardness without losing its toughness,which has extremely high application value.

Process Details:

1.Nominal Quenching temperature:850~870℃

2.Hold at this temperature then quench in oil or water

3.Tempering as soon as possible when the temperature low to ambient temperature

4.Heat the steel carefully to a suitable temperature selected by reference to a tempering chart or table

5.The usual tempering temperature is 600°C which depending on the actual requirements

6.keep the material out of the furnace ,then cool in the air

Quenching Hardness:55-59HRC

Tempering temperature:640-760°C,Corresponding hardness:28-32HRC.

Mechanical Property( for reference only)

1.Tensile strength: ≥1000MPa

2.Yield point:≥850MPa

3.Percentage reduction of area after fracture: ≥55%

4.Elongation after fracture: ≥12%

5.Impact test (+20°C): 100J

Delivery Condition

1.Shape:Round/Square / Flat/Shafts/Rollers/Blocks

2.Surface condition:Black surface/Bright surface

3.Heat Treatment:Normalized/Annealed/QT

4.Straightness:Max 3mm/m(Enhanced straightness may be available on request)

5.Length:3000-5800mm suitable for 20″container. above 6000mm,suitable for 40″ container

6.Grain Size: 5-8 acc to ASTM E112-96

7.Typcial Hardness:HRC28-32

8.Ultrasonic Standard: Sep1921/ASTM A388/EN 10228-3

9.Non Metallic Inclusion: 2 max acc to ASTM E45 /K4≤20 acc to DIN 50602

10.Forging Ratio: minimum 4 : 1

11.Marking: Grade/Weight/Length/Size/Heat Number

Quality Certification

A material test report(Inspection Certificate EN 10204 3.1) will be provided, documenting the following:

1.Chemical analysis

2.Mechanical properties

3.Surface hardness

4.Non Metallic Inclusion

5.Heat Treatment Process

6.Grain size

7.Forging ratio

8.Ultrasonic test report

Supply Size & Condition For SAE 4340

- Round Bars: Dia.80 – 1,000mm as Forged

- Flat / Square Bars: Thickness Max.800mm

- Shafts, Rollers, Blocks: Customized or According to Drawing

- Rolled Round Bars: Dia.16 – 200mm with UT Assurance

Heat treatment:Quenched and Tempered (+QT), Normalizing (+N), Annealing (+A)

Surface finish:Black / Rough turned / Peeled