SAE 4140 ALLOY STEEL BAR|AISI 4140-ASTM A29

SAE 4140 Alloy Steel manufacturers and suppliers, supplied with round rods,square/flat bars,rollers,shafts,blocks and forging pieces.

SAE 4140 grade is a low-alloy steel including chromium and molybdenum as strengthening elements which has good strength and toughness, ductility,weldability and machinability.

SAE 4140 is widely used in the automotive, agricultural ,oil and gas industry. Typical uses are forged gears and shafts, spindles, fixtures, jigs and collars.

| Chemical Composition | ||||||||

|

National Standard |

Grade | C | Si | Mn | Cr | Mo | P | S |

| EN/DIN |

42CrMo4 (1.7225) |

0.38-0.45 | ≤0.4 | 0.6-0.9 | 0.9-1.2 | 0.15-0.3 | ≤0.025 | ≤0.035 |

| SAE | 4140 | 0.38-0.43 | 0.15-0.35 | 0.7-1.0 | 0.8-1.1 | 0.15-0.25 | ≤0.035 | ≤0.04 |

| JIS | SCM440 | 0.38-0.43 | 0.15-0.35 | 0.6-0.85 | 0.9-1.2 | 0.15-0.3 | ≤0.035 | ≤0.04 |

| GB | 42CrMo | 0.38-0.45 | 0.17-0.37 | 0.5-0.8 | 0.9-1.2 | 0.15-0.25 | ≤0.035 | ≤0.035 |

| BS | EN19 | 0.35-0.45 | 0.15-0.35 | 0.5-0.8 | 0.9-1.5 | 0.2-0.4 | 0.035 | 0.035 |

IS SAE 4140 Same As AISI 4140?

With the increasing international trade volume of steel materials, SAE/AISI steel grade codes are often encountered in inquiries, such as the common AISI 4140 and SAE 4140, SAE 1045 and AISI 1045, AISI 4340 and SAE 4340 and so on.

So the question is, do they represent the same material?

First, we need to clarify that AISI and SAE stand for the American Iron and Steel Institute (A.I.S.I.) and the Society of Automotive Engineers (S.A.E.).These two associations participated in the standardization of the steel numerical coding system, and gradually integrated into the AISI/SAE steel grade nomenclature joint system.

The value of SAE/AISI is that technical engineers can obtain general information (though not comprehensive) about steel types and their grades through this steel grade nomenclature system.So far, the steel grade codes of SAE and AISI are often quoted in the quotation and product certification of steel products in the United States, without deliberately distinguishing them.

Therefore, from the above, it can be seen that “4140”, “AISI 4140” or “SAE 4140”, although written differently, but in most general industrial applications,any of the above is considered equivalent.

SAE 4140 Steel Physical Property

| Density, g/cm3 | 7.85 |

| Melting point,℃ | 1390 |

|

Specific heat capacity,(0~100℃),J/(kg.k) |

482 |

|

Linear expansion coefficient,10^-6/k |

0~100℃ |

| 12.43 | |

| Poisson's ratio | 0.28 |

| Elastic Modulus,Mpa | 211722 |

| Shear modulus,Mpa | 82473 |

Critical Temperature for Heat Treatment of SAE 4140

- Ac1:730℃

- Ac3:780℃

- Ar1:690℃

- Ms:360℃

Heat Treatment For SAE 4140

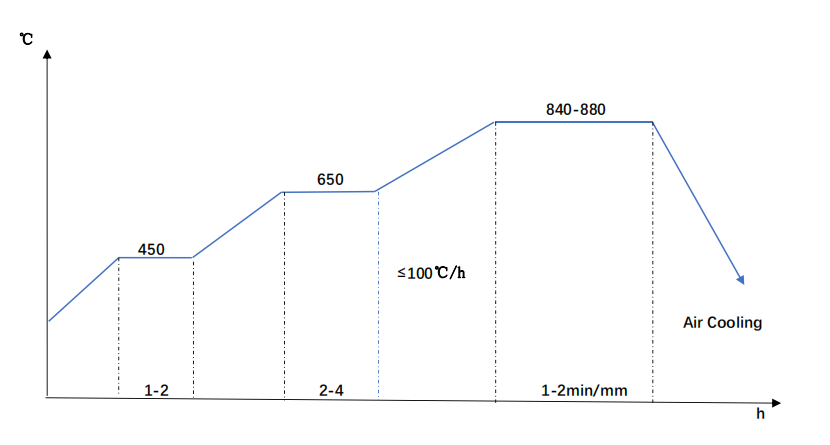

- Normalizing

After hot working, SAE 4140 normalizing,can refine the grains, homogenize the structure, and prepare the structure for the final heat treatment(Especially for Q&T).

Process Details:

- Normalizing temperature:840-880°C

- Heating and heat preservation in steps at 450°C,650°C

- Controlling the heating speed to ensure uniform heating.

- Air cooling,which can be accelerated by blowing air or water mist.

SAE 4140 Normalizing Diagram

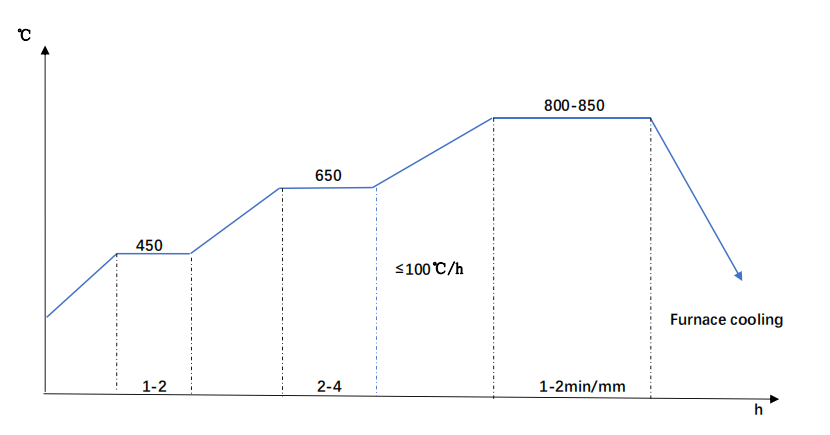

- Annealing

For the annealing of SAE 4140, the main purpose is to reduce hardness, improve machinability and reduce residual stress.

Common annealing methods are generally divided into the following types.

- Complete annealing (recrystallization annealing):800-850°C

- Isothermal annealing:675°C

- Stress relief annealing:600-650°C

Cooling Method:Furnace Cooling

SAE 4140 Annealing Diagram

- Quenching & Tempering(QT) For SAE 4140

Quenching and tempering refers to a heat treatment process used to improve the comprehensive mechanical properties of steel materials. That is, after quenching, it is subjected to high temperature tempering treatment.

For SAE 4140 steel,the purpose of quenching and tempering is to make the material obtain a good combination of strength and toughness, which not only has high strength, but also has excellent toughness, plasticity, and cutting performance.

Process Details:

1.Quenching temperature:840-880°C

2.Hold at this temperature then quench in oil or water

3.Tempering as soon as possible when the temperature low to ambient

4.Heat uniformly to the suitable temperature of 540-680°C

5.keep the material out of the furnace ,then cool in the air

Quenching Hardness:55-59HRC

Tempering temperature:220-650°C,Corresponding hardness:28-58HRC.

Mechanical Property For SAE 4140 in Quenched and Tempered condition

1.Tensile strength: ≥1100MPa

2.Yield point:≥950MPa

3.Percentage reduction of area after fracture: ≥45%

4.Elongation after fracture: ≥12%

5.Impact test (+20°C): Transverse – 26~42J; Longitud – 49~55J

Delivery Condition

1.Shape:Round/Square / Flat/Shafts/Rollers/Blocks

2.Surface condition:Black surface/Bright surface

3.Heat Treatment:Normalized/Annealed/QT

4.Straightness:Max 3mm/m(Enhanced straightness may be available on request)

5.Length:3000-5800mm suitable for 20″container. above 6000mm,suitable for 40″ container

6.Grain Size: 5-8 acc to ASTM E112-96

7.Ultrasonic Standard: Sep1921/ASTM A388/EN 10228-3

8.Typical Hardness:HB269-302

9.Non Metallic Inclusion: 2 max acc to ASTM E45 /K4≤20 acc to DIN 50602

10.Forging Ratio: minimum 4 : 1

11.Ingot Melting:EAF+LF+VD

12.Marking: Grade/Weight/Length/Size/Heat Number

Quality Certification

A material test report(Inspection Certificate EN 10204 3.1) will be provided, documenting the following:

1.Chemical analysis

2.Mechanical properties

3.Surface hardness

4.Non Metallic Inclusion

5.Heat Treatment Process

6.Grain size

7.Forging ratio

8.Ultrasonic test report

Supply Size & Condition For SAE 4140

- Round Bars: Dia.80 – 1,000mm as Forged

- Flat / Square Bars: Thickness Max.800mm

- Shafts, Rollers, Blocks: Customized or According to Drawing

- Rolled Round Bars: Dia.14 – 350mm with UT Assurance

Heat treatment:Quenched and Tempered (+QT), Normalizing (+N), Annealing (+A)

Surface finish:Black / Rough turned / Peeled