DIN 1.3255 HIGH SPEED STEEL | S18-1-2-5 | SKH3

DIN 1.3255/S18-1-2-5 high speed steel manufacturers and suppliers, supplied in round rods,flat/square bars,plates,sheets,wire and blocks.

DIN 1.3255/ S18-1-2-5 High Speed Steel is a Tungsten-Cobalt high speed tool steel adding 5% cobalt according to DIN standard which is similar to 1.3355 steel .Because of the addition of Cobalt content, it improves the high temperature hardness and red hardness.

DIN 1.3255/S18-1-2-5 steel has excellent cutting performance and excellent wear resistance which are widely used in Drills, Milling Cutters, Milling Cutters, Thread Cutting Tools, Knurling Tools, Broaches etc.

Chemical Composition For DIN 1.3255 HSS

| C | Cr | V | W | Mo | Co | |

| Min | 0.75 | 3.8 | 1.4 | 17.5 | 0.5 | 4.5 |

| Max | 0.83 | 4.5 | 1.7 | 18.5 | 0.8 | 5.0 |

Related Specification

USA | ASTM : T4

JAPAN | JIS:SKH3

Critical Temperature for Heat Treatment of DIN 1.3255 HSS

Ac1:842-872°C

DIN 1.3255 HSS Forging

It is important to heat the DIN 1.3255 HSS in steps so that the material is heated slowly and evenly.It is usually heated slowly at low temperature and rapidly heated to the initial forging temperature between 1065-1180°C at high temperature.

When the temperature is lower than 900°C during forging, it needs to be reheated, otherwise the material is easy to crack. This requires us to control the final forging temperature around 900°C.

Timely annealing for DIN 1.3255 HSS after forging is very necessary.

Heat Treatment For DIN 1.3255 HSS

- Annealing

Annealing for DIN 1.3255 HSS is recommended after hot working and before rehardening.Heat the temperature to 840-900°C at a rate of no more than 220°C per hour.The holding time depends on the thickness of the material,usually one hour per inch of thickness(at least two hours).

According to the cooling method, it is divided into softening annealing and isothermal annealing.

For isothermal annealing,it should be cooled to 740-760°C first, then kept for 2-4h, and then cooled to 500-600°C for slow cooling.Hardness below 262HBW.

For Softenig annealing,it should be cooled to 500-600°C at 20-30°C/h and then furnace cooled.Hardness below 262HBW

- Hardening & Tempering For DIN 1.3255 HSS

1.Preheat DIN 1.3255 HSS to 550°C ,then up to 850°C

2.Heat to the final hardening temperature of 1270- 1310°C and make sure the material must be heated through.

3.Quench in the warm oil,and then complete the quench in air.(care must be taken at this step)

4.Quenching hardness above 63HRC

5.DIN 1.3255/S18-1-2-5 tool steel is suitable for vacuum hardening.

6.Tempering must be done immediately after quenching

7.Heat thoroughly and uniformly to the tempering temperature 560-590°C

8.Hold at the temperature for at least two hours (one hour per inch of the total thickness)

9.Triple tempering is strongly recommended for DIN 1.3255/S18-1-2-5 HSS

10.Tempering hardness above 63HRC.

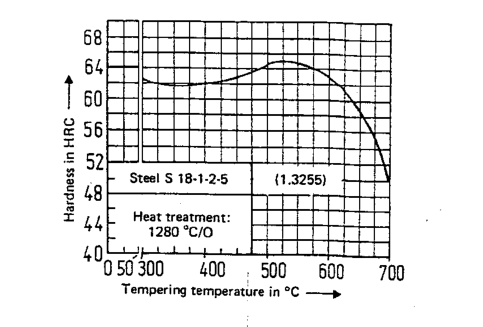

DIN 1.3255 HSS Tempering Vs Hardness

Heat Treatment:1280°C,Oil quenching.

Supply Size & Condition For DIN 1.3255 HSS

| Round bar | ||||

| Diameter | 1-16mm | 10-50mm | 50-180mm | 180-300mm |

| Process | Cold Drawn | Hot Rolled | Hot Forged | Free Forging |

| Flat bar | ||||

| Thickness | 1-2.5mm | 1.5-20mm | 20-300mm | |

| Width | Max 800mm | Max 800mm | Max 800mm | |

| Process | Cold Drawn | Hot Rolled | Hot Forged | |

|

Shape:Round / Square / Flat Bars, Sheet, Plate,Wire. Surface Condition:Black/Turning/grinding |

||||

Quality Certification

DIN 1.3255/HS18-1-2-5 high speed steel is supplied in accordance with our ISO 9001:2008 registration.

A material test report(Inspection Certificate EN 10204 3.1) will be provided, documenting the following:

1.Chemical analysis

2.Surface hardness

3.Non Metallic Inclusion

4.Macroscopic Structure

5.Decarburization

6.Eutectic carbides distribution

7.Ultrasonic test report

8.Surface quality