DIN 1.3243 HIGH SPEED STEEL | HS6-5-2-5 | SKH55

DIN 1.3243/HS6-5-2-5 high speed tool steel manufacturers and suppliers,supplied in round rods,square bars,flat bars,plates,sheets and blocks.

DIN 1.3243 is a high speed tool steel adding 5% cobalt which is similar to HS6-5-2-5 steel . the properties of 1.3243/HS6-5-2-5 tool steel will be obviously improved after special heat treating process and the hardness can reach 66 HRC.

DIN 1.3243/HS6-5-2-5 tool steel also offers excellent cutting performance which is used for broaches,saw blades,reamers,milling cutters and end mills.

Chemical Composition For DIN 1.3243 HSS

| C | Si | Mn | Cr | Mo | V | W | Co | |

| Min | 0.87 | 0 | 0 | 3.8 | 4.7 | 1.7 | 5.9 | 4.5 |

| Max | 0.95 | 0.45 | 0.4 | 4.5 | 5.0 | 2.1 | 6.7 | 5.0 |

Related Specification

CHINA|GB:W6Mo5Cr4V2Co5

USA | ASTM :M35

JAPAN | JIS:SKH55

Critical Temperature for Heat Treatment of DIN 1.3243

- Ac1:825-851°C

- Ms:220°C

DIN 1.3243 HSS Forging

DIN 1.3243 HSS is a high-alloy steel with poor thermal conductivity. It should be heated in sections. The heating rate is slower at low temperature and rapid heating at high temperature.Strictly control the furnace temperature so that the material is heated evenly inside and outside.

The initial forging temperature of DIN 1.3243 high-speed steel is controlled between 1040-1150°C.If the final forging temperature is too low, the material will be easily cracked. If it is too high, the grains will be coarse and the material properties will be affected.Therefore, the final forging temperature should be strictly controlled at about 900°C.

After forging, DIN 1.3243 HSS should be annealed in time to eliminate internal stress.

Heat Treatment For DIN 1.3243

- Annealing

Generally speaking,DIN 1.3243/HS6-5-2-5 high speed steel is supplied in the annealed and machineable condition.While DIN 1.3243/HS6-5-2-5 has been hot worked, forged, or hardened,it is necessary to be annealed in time.

For DIN 1.3243 HSS annealing,it can be divided into softening annealing and isothermal annealing.

Process Details:

1.Heating temperature at 840-860°C

2.Annealing heating temperature should be uniform and slow heating

3.For isothermal annealing,it should be cooled to 740-760°C first, then kept for 2-4h, and then cooled to 500-600°C for slow cooling.Hardness below 269HBW

4.For Softenig annealing,it should be cooled to 500-600°C at 20-30°C/h and then furnace cooled.Hardness below 285HBW

- Hardening & Tempering For DIN 1.3243 HSS

1.Preheat DIN 1.3243 to 450-500°C ,then up to 800-850°C with rate of 24 s/mm.

2.Heat to the final hardening temperature of 1210-1250°C and make sure the material must be heated through.

3.Quench in the warm oil or brine,and then complete the quench in air.(care must be taken at this step)

4.Tempering must be done immediately after quenching.

5.Heat thoroughly and uniformly to the tempering temperature of 550-570°C.

6.Hold at the temperature for at least two hours (one hour per inch of the total thickness).

7.Triple tempering is strongly recommended for DIN 1.3243/HS6-5-2-5 high speed steel.

8.Hardness above 64HRC.

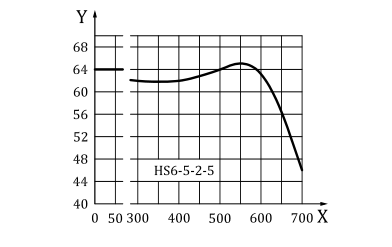

DIN 1.3243 HSS Tempering Vs Hardness

Heat Treatment:1210°C,Oil quenching

X:Tempering temperature,°C

Y:Hardness,HRC

Supply Size & Condition For DIN 1.3243 HSS

| Round bar | ||||

| Diameter | 1-16mm | 10-50mm | 50-180mm | 180-300mm |

| Process | Cold Drawn | Hot Rolled | Hot Forged | Free Forging |

| Flat bar | ||||

| Thickness | 1-2.5mm | 1.5-20mm | 20-300mm | |

| Width | Max 800mm | Max 800mm | Max 800mm | |

| Process | Cold Drawn | Hot Rolled | Hot Forged | |

|

Shape:Round / Square / Flat Bars, Sheet, Plate,Wire. Surface Condition:Black/Turning/grinding |

||||

Quality Certification

DIN 1.3243/HS6-5-2-5 high speed steel is supplied in accordance with our ISO 9001:2008 registration.

A material test report(Inspection Certificate EN 10204 3.1) will be provided, documenting the following:

1.Chemical analysis

2.Surface hardness

3.Non Metallic Inclusion

4.Macroscopic Structure

5.Decarburization

6.Eutectic carbides distribution

7.Ultrasonic test report

8.Surface quality