AISI 1045|1.1191|C45E|S45C

AISI 1045 steel is a medium tensile steel supplied as forged or normalized condition. It has a tensile strength of 570 – 700 MPa and Brinell hardness range 170 to 210HB.AISI 1045 steel offers good strength, toughness,wear resistance and impact properties in either the normalized or hot rolled condition.AISI 1045 steel has a low through-hardening capability with only sections of size around 60 mm being recommended as suitable for tempering and through-hardening. However, it can be efficiently flame or induction hardened in the normalized or hot rolled condition to obtain typical surface hardness up to HRC 58. nitriding is not recommended due to lack of alloy elements.This steel can be readily welded and machined providing correct procedures are followed.

1.AISI 1045 steel Supply Form & Size

| Form of Supply | Size(mm) | Length(mm) |

| Round bar | Φ6-Φ1,000 | 3,000-10,000 |

| Square bar | 100x100-600x600 | 3,000-6,000 |

| Plate/Sheet |

Thickness :20-400 Width:80-1,000 |

2,000-6,000 |

| Flat bar/Blcoks |

Thickness :120-800 Width:120-1,500 |

2,000-6,000 |

2.AISI 1045 steel Surface Finish&Tolerance

| Surface Finish | Black-Forged | Black-Rolled | Turned | Grinding | Polished | Peeled | Cold Drawn |

| Tolerance | (0,+5mm) | (0,+1mm) | (0,+3mm) | Best h9 | Best h11 | Best H11 | Best H11 |

3.Chemical Composition&Related Specifications

| Grade | C | Si | Mn | P | S |

| 1045 | 0.43-0.50 | 0.15-0.35 | 0.60-0.90 | ≤ 0.04 | ≤ 0.05 |

| Germany | Australia | China | Japan |

| C45E/1.1191 | 1045 | 45# | S45C |

4.AISI 1045 steel Mechanical Property

| Surface Finish | Tensile Strength Mpa | Yield Strength Mpa | Elongation, % | Hardness,HB |

| Cold Drawn | 640–850 | 500–650 | ≥8 | 190–270 |

| Smooth Turned | 570–700 | 300–450 | 14 – 30 | 170–210 |

| Hot Rolled / Forged | 570–700 | 300–450 | 14 – 30 | 170–210 |

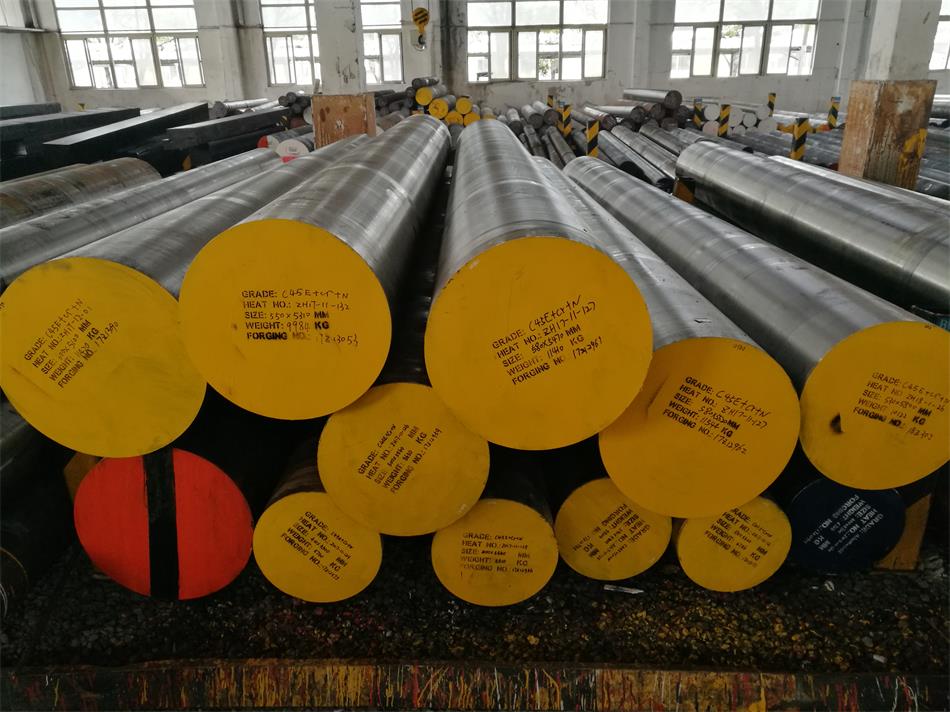

5.AISI 1045 steel Forging

Forging temperature: 1100 oC – 1200 oC,hold enough time for the steel to be thoroughly heated.Don’t forge below temperature 850°C.AISI 1045 steel should be cooled as slowly as possible in still air or in sand after forged.

6.Heat Treatment

- Normalizing:870℃-920℃,Cool in air

- Annealing:800℃-850℃,Cool in furnace

- Hardening:820 – 860°C/water or oil quench

- Tempering:550°C – 660°C, cool in still air

- Stress Relieving:550°C – 660°C ,cool in still air

- Flame and Induction Hardening:830°C – 860°C,quick quench in oil or water.Temper at 150°C – 200°C will reduce stresses in the case with minimal effect on its hardness.

7.Machining

AISI 1045 steel has good machinability in normalized as well as the hot rolled condition. Operations such as tapping, milling, broaching, drilling, turning and sawing can be easily performed on the steel using suitable feeds, tool type and speeds as per the recommendations given by the machine manufacturers.

8.Application

AISI 1045 is widely used for all industrial applications requiring more wear resistance and strength. Typical applications of AISI 1045 are as follows:

Axles, bolts, connecting rods, studs, rams, pins,rolls, spindles, ratchets, crankshafts, torsion bars,sockets, worms, light gears, guide rods etc.