SAE 1045 CARBON STEEL|AISI 1045-ASTM A29

SAE 1045 Carbon Steel manufacturers and suppliers, supplied with round rods,square/flat bars,rollers,shafts,blocks and forging pieces.

SAE 1045/AISI 1045 Carbon Steel is a medium carbon steel which is characterized by good weldability, good machinability, high strength and impact properties in either the normalized or hot forged condition.

SAE 1045/AISI 1045 steel is widely used for axles, bolts, forged connecting rods, crankshafts, torsion bars, light gears, guide rods etc.

| Chemical Composition | ||||||||

|

National Standard |

Grade | C | Si | Mn | Cr | Mo | P | S |

| DIN |

C45 (1.1191) |

0.42-0.5 | ≤0.4 | 0.5-0.8 | ≤0.4 | ≤0.1 | ≤0.035 | ≤0.035 |

| SAE | 1045 | 0.43-0.5 | 0.2-0.4 | 0.6-0.9 | – | – | ≤0.04 | ≤0.05 |

| JIS | S45C | 0.42-0.48 | 0.15-0.35 | 0.6-0.9 | – | – | ≤0.03 | ≤0.035 |

| GB | 45 | 0.42-0.5 | 0.17-0.37 | 0.5-0.8 | ≤0.25 | – | ≤0.035 | ≤0.035 |

SAE 1045 Steel Physical Property

| Density, g/cm3 | 7.86 |

| Melting point,℃ | 1433 |

| Specific heat capacity,(0~100℃),J/(kg.k) | 577.78(200℃) |

| Linear expansion coefficient,10^-6/k | 0~100℃ |

| 11.7 | |

| Poisson's ratio | 0.269 |

| Elastic Modulus,Mpa | 209000 |

| Shear modulus,Mpa | 82300 |

| Thermal conductivity,W/(m.K) | 46.89(200℃) |

| Resistivity,10^-8 Ω.m | 32.0(200℃) |

Critical Temperature for Heat Treatment of SAE 1045

- Ac1:724℃

- Ac3:780℃

- Ar1:682℃

- Ar3:751℃

Heat Treatment For SAE 1045

- Normalizing

For SAE 1045 steel, normalizing can be used as a preliminary heat treatment to refine grains and homogenize the structure.For parts with low requirements for low load use,it can also be used as its final heat treatment.

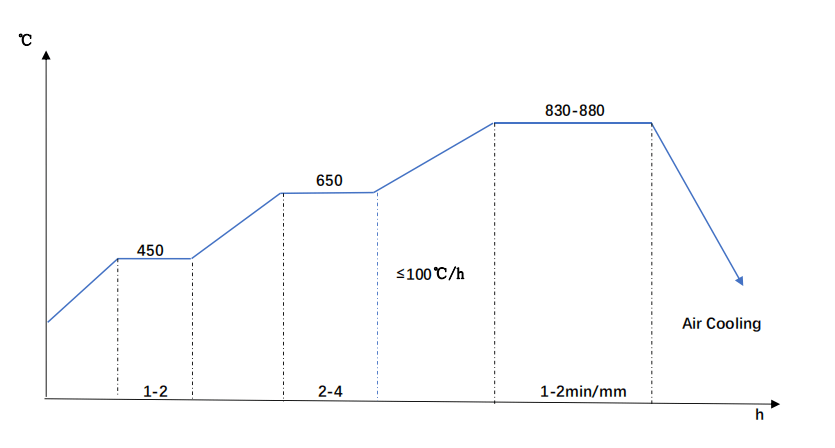

For normalizing of SAE 1045 steel,heating and holding in steps is a recommended practice, which can be selected at 450°C and 650°C respectively.The final normalizing temperature is 830-880°C,and the holding time is determined according to the thickness of the material.Air cooling from the furnace after holding,and sometimes choose to blow water mist to speed up cooling.

SAE 1045 Normalizing Diagram

- Annealing

For annealing of SAE 1045 steel,the main purpose is to reduce the material stress,soften the material,and improve the turning performance.

SAE 1045 annealing temperature is usually controlled at 820-840°C,different from the air cooling of normalizing, the annealing of SAE 1045 requires strict control of the cooling rate and slow cooling in the furnace.

SAE 1045 Mechanical Property in Annealed condition

| Tensile,Mpa | Yield,Mpa | Elongation,% | Reduction,% | Charpy Impact,J | Hardness,HBW |

| ≥532 | ≥280 | ≥32 | ≥49 | ≥60 | 160-200 |

- Quenching & Tempering(QT) For SAE 1045

For important SAE 1045 steel parts, there are often higher comprehensive performance requirements, which are often met by quenching and tempering heat treatment.

Process Details:

1.Quenching temperature:820-840°C

2.Hold at this temperature then quench in water

3.Tempering as soon as possible after quenched

4.Heat uniformly to the suitable temperature of 540-680°C

5.keep the material out of the furnace ,then cool in the air

Quenching Hardness:55-60HRC

Tempering temperature:540-580°C,Corresponding hardness:228-269HBW

Tempering temperature:580-640°C,Corresponding hardness:192-228HBW

Tempering temperature:640-680°C,Corresponding hardness:170-192HBW

Mechanical Property For SAE 1045 in Quenched and Tempered condition

820-840°C Water Quenched,followed by tempeing with 560-620°C

- Tensile strength: 700-850MPa

- Yield strength:450-560MPa

- Elongation:15-17%

- Reduction of area:45-50%

- Impact value:60-80J

- Hardness:196-241HBW

Delivery Condition

1.Shape:Round/Square / Flat/Shafts/Rollers/Blocks

2.Surface condition:Black surface/Bright surface

3.Heat Treatment:Normalized/Annealed/QT

4.Straightness:Max 3mm/m(Enhanced straightness may be available on request)

5.Length:3000-5800mm suitable for 20″container. above 6000mm,suitable for 40″ container

6.Grain Size: 5-8 acc to ASTM E112-96

7.Ultrasonic Standard: Sep1921/ASTM A388/EN 10228-3

8.Non Metallic Inclusion: 2 max acc to ASTM E45 /K4≤20 acc to DIN 50602

9.Forging Ratio: minimum 4 : 1

10.Marking: Grade/Weight/Length/Size/Heat Number

Quality Certification

A material test report(Inspection Certificate EN 10204 3.1) will be provided, documenting the following:

1.Chemical analysis

2.Mechanical properties

3.Surface hardness

4.Non Metallic Inclusion

5.Heat Treatment Process

6.Grain size

7.Forging ratio

8.Ultrasonic test report

Supply Size & Condition For SAE 1045

- Round Bars: Dia.80 – 1,000mm as Forged

- Flat / Square Bars: Thickness Max.800mm

- Shafts, Rollers, Blocks: Customized or According to Drawing

- Rolled Round Bars: Dia.14 – 350mm with UT Assurance

Heat treatment:Quenched and Tempered (+QT), Normalizing (+N), Annealing (+A)

Surface finish:Black / Rough turned / Peeled