SNCM220 CASE HARDENING STEEL-JIS G4103

SNCM220 Case Hardening steel manufacturers and suppliers, supplied in round rods,square/flat bars,rollers,shafts,blocks and forging pieces.

SNCM220 Case Hardening Steel is defined as low Cr-Ni-Mo alloy steel as per JIS G4103 Standard.It has high surface hardness, good wear resistance and fatigue strength after nitriding heat treatment.SNCM220 is mainly used for automobile bearings, drive shafts, gears, screws, cutting tools and other products which need impact resistance and wear resistant.

1.Chemical Composition

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

| SNCM220 | 0.17-0.23 | 0.15-0.35 | 0.6-0.9 | ≤ 0.03 | ≤ 0.03 | 0.4-0.65 | 0.4-0.7 | 0.15-0.30 |

2.Related Specifications

ASTM:8620

BS:805M20

EN/DIN:20NiCrMo2-2/21NiCrMo2

GB:20CrNiMo

3.Heat Treatment & Mechanical Property

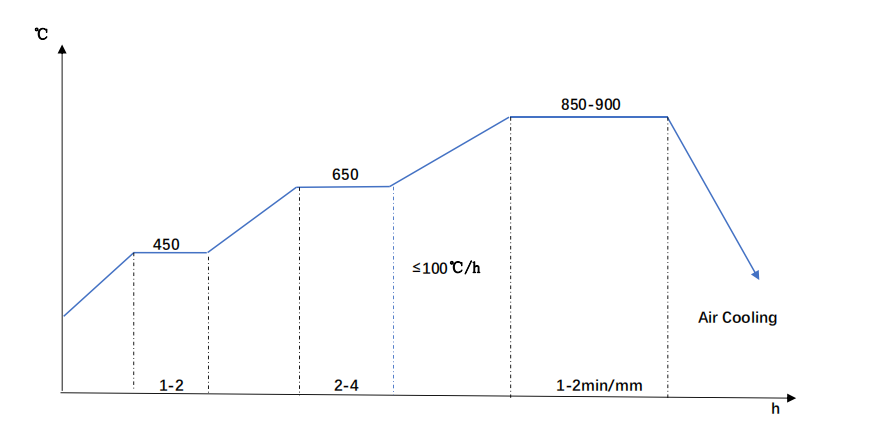

SNCM220 Normalizing Diagram

SNCM220 Steel Normalizing Details

1.Normalize temperature:850-900℃

2.Three steps of temperature raising for evenly heating.

3.suitable holding time depends on the dimension.

4.Air cooling.

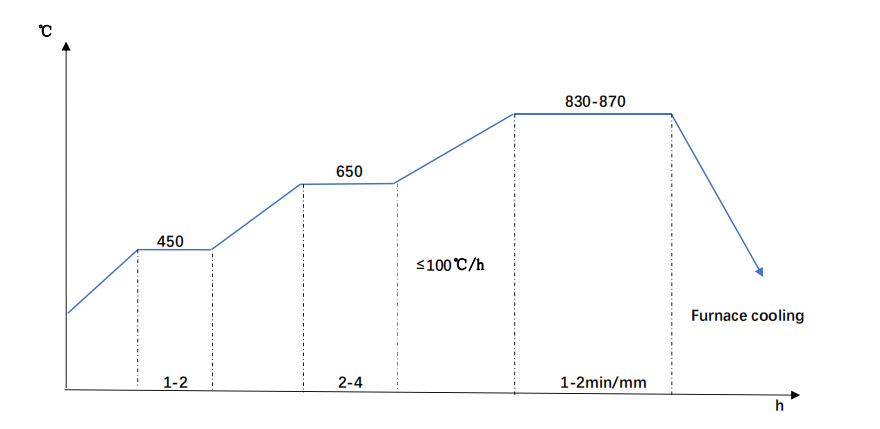

SNCM220 Annealing Diagram

SNCM220 Steel Annealing Details

1.Annealing temperature:830-870℃

2.Enough time for temperature holding

3.Cooling in the furnace.

4.Max hardness:200HB

SNCM220 Mechanical Property -Normalizing(+N) Vs Annealing(+A)

| Tensile,Mpa | Yield,Mpa | Elongation,% | Reduction,% | Charpy Impact, J | Brinell Hardness,HB | |

| +N | ≥635 | ≥355 | ≥26.3 | ≥60 | ≥100 | 183 |

| +A | ≥535 | ≥385 | ≥31.3 | ≥62 | ≥112 | 149 |

4.Supply Form & Size

- Round Bars: Dia.80 – 1,000mm as Forged

- Flat / Square Bars: Thickness Max.800mm

- Shafts, Rollers, Blocks: Customized or According to Drawing

- Rolled Round Bars: Dia.16 – 130mm with UT Assurance

Heat treatment:Quenched and Tempered (+QT), Normalizing (+N), Annealing (+A)

Surface finish:Black / Rough turned / Peeled