20NICRMO2-2 CASE HARDENING STEEL |20NICRMO2

20NiCrMo2-2/DIN 1.6523 Case Hardening steel manufacturers and suppliers, supplied in round rods,square/flat bars,rollers,shafts,blocks and forging pieces.

20NiCrMo2-2 is defined as low Ni-Cr-Mo alloy steel as per EN10084 standard.It has good weldability,toughness,and machinability,but low in corrosion resistance.20NiCrMo2-2 is suitable for parts which require high hardness and good wear resistance after nitriding.This material is generally supplied in annealed condition with hardness below 212HB.

1.Chemical Composition

| Grade | C | Si | Mn | P | S | Cr | Ni | Mo |

|

20NiCrMo2-2 (DIN1.6523) |

0.17-0.23 | ≤ 0.4 | 0.65-0.95 | ≤ 0.025 | ≤ 0.035 | 0.35-0.7 | 0.4-0.7 | 0.15-0.25 |

| 8620 | 0.18-0.23 | 0.15-0.35 | 0.7-0.9 | ≤ 0.035 | ≤ 0.04 | 0.4-0.6 | 0.4-0.7 | 0.15-0.25 |

2.Related Specifications

ASTM:8620

BS:805M20

JIS:SNCM220

GB:20CrNiMo

3.Heat Treatment & Mechanical Property

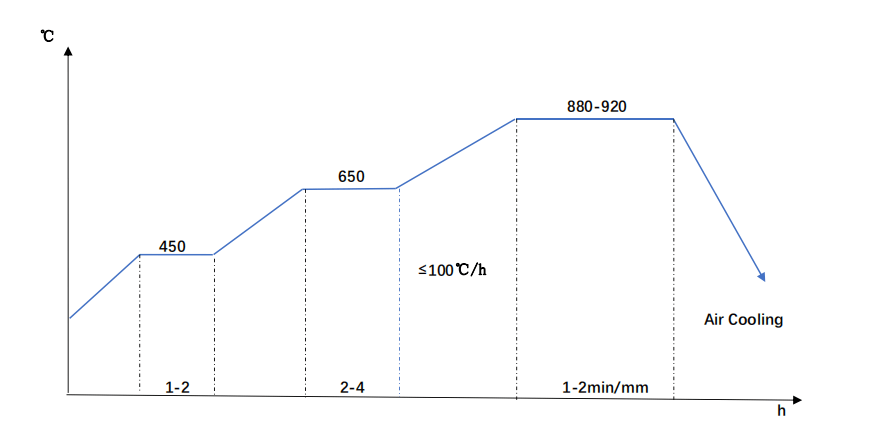

- Normalizing: 880 – 920°C,Cooling in air

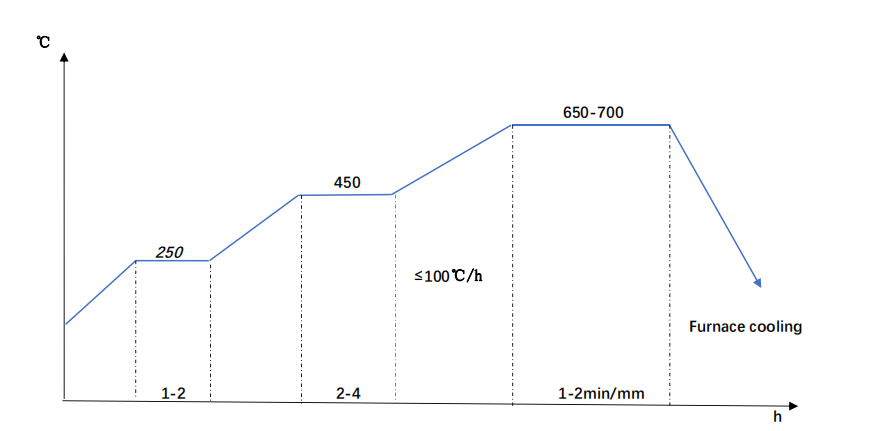

- Annealing:650 – 700°C,Cooling in furnace

- Carburizing:880 – 980°C

- Core Hardening:860 – 900°C,oil/water

- Case Hardening:780-820°C,oil/water

- Tempering:150 – 200°C,Cooling in air

20NiCrMo2-2 Normalizing Diagram

20NiCrMo2-2 Annealing Diagram

20NiCrMo2-2 Mechanical Property -Normalizing(+N) Vs Annealing(+A)

| Tensile,Mpa | Yield,Mpa | Elongation,% | Reduction,% | Charpy Impact, J | Brinell Hardness,HB | |

| +N | Min 635 | Min 355 | Min 26.3 | Min 60 | Min 100 | 183 |

| +A | Min 535 | Min 385 | Min 31.3 | Min 62 | Min 112 | 149 |

20NiCrMo2-2 Hardenability Limits

| Distance from quenched end mm | 1.5 | 3.0 | 5.0 | 7.0 | 9.0 | 11 | 13 | 15 | 20 | 25 | 30 | 35 | 40 | |

|

20NiCrMo2-2+H |

Min | 41 | 37 | 31 | 25 | 22 | 20 | - | - | - | - | - | - | - |

| Max | 49 | 48 | 45 | 42 | 36 | 33 | 31 | 30 | 27 | 25 | 24 | 24 | 23 | |

|

20NiCrMo2-2+HH |

Min | 44 | 41 | 36 | 31 | 27 | 24 | 22 | 21 | - | - | - | - | - |

| Max | 49 | 48 | 45 | 42 | 36 | 33 | 31 | 30 | 27 | 25 | 24 | 24 | 23 | |

|

20NiCrMo2-2+HL |

Min | 41 | 37 | 31 | 25 | 22 | 20 | - | - | - | - | - | - | - |

| Max | 46 | 44 | 40 | 36 | 31 | 29 | 27 | 26 | 23 | 21 | 20 | 20 | - | |

4.Supply Form & Size

- Round Bars: Dia.80 – 1,000mm as Forged

- Flat / Square Bars: Thickness Max.800mm

- Shafts, Rollers, Blocks: Customized or According to Drawing

- Rolled Round Bars: Dia.16 – 130mm with UT Assurance

Heat treatment:Quenched and Tempered (+QT), Normalizing (+N), Annealing (+A)

Surface finish:Black / Rough turned / Peeled