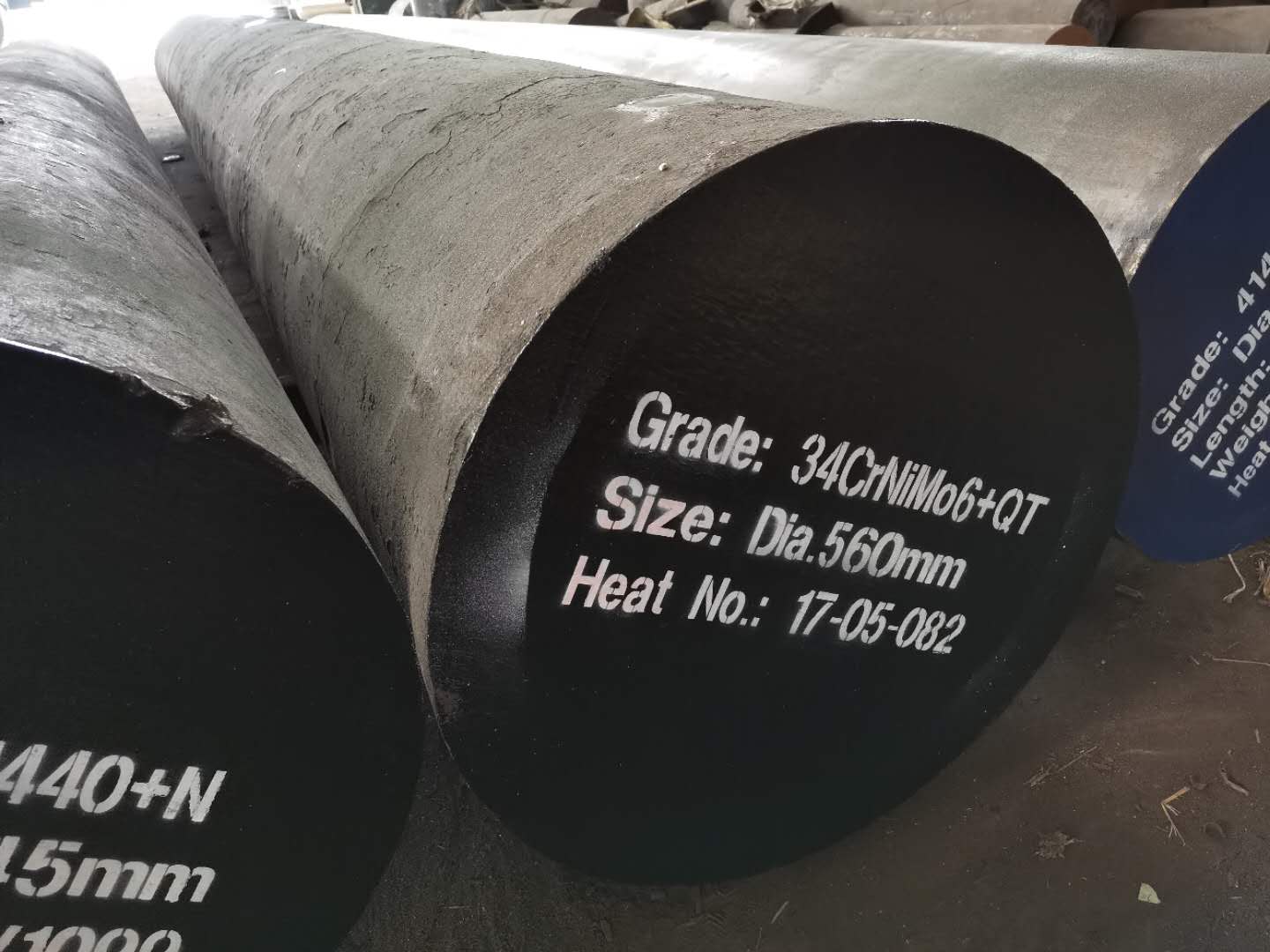

34CRNIMO6+QT|DIN 1.6582 QUALITY ALLOY STEEL

34CrNiMo6/DIN 1.6582 Alloy Steel manufacturers and suppliers,supplied with round rods,square/flat bars,rollers,shafts,blocks and forging pieces.

34CrNiMo6/1.6582 Alloy Steel is defined as Engineering steel which contains low Cr-Ni-Mo as strength elements as per EN10083 Standard.This material has high strength,toughness and good hardenability after quenched and tempered,but also has poor weldability,high sensitivity on hydrogen flaking and temper brittleness.34CrNiMo6/1.6582 Alloy Steel is widely used in heavy duty Shafts, Gears, Axles, Spindles, Couplings, Pins etc.

1.Chemical Composition

| Grade | C | Mn | P | S | Si | Ni | Cr | Mo |

| 34CrNiMo6/1.6582 | 0.30-0.38 | 0.50-0.80 | ≤ 0.025 | ≤ 0.035 | ≤ 0.04 | 1.3-1.7 | 1.3-1.7 | 0.15-0.3 |

2.Related Specifications

ASTM:4340

BS:817M40/EN24

JIS:SNCM449

GB:40CrNiMo

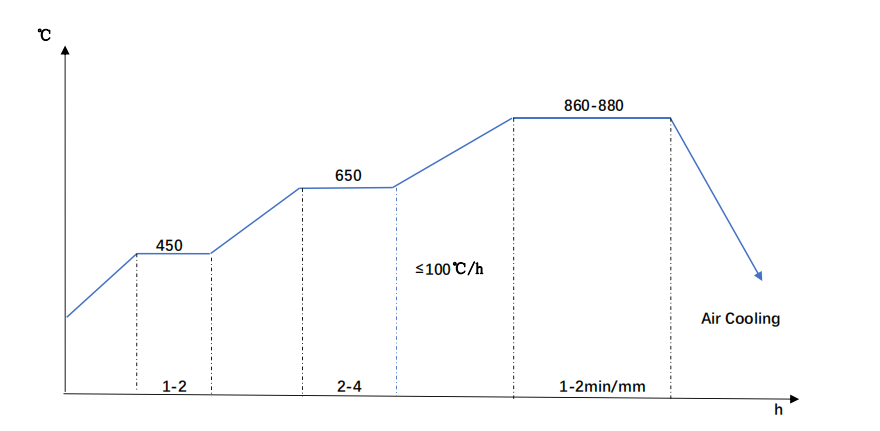

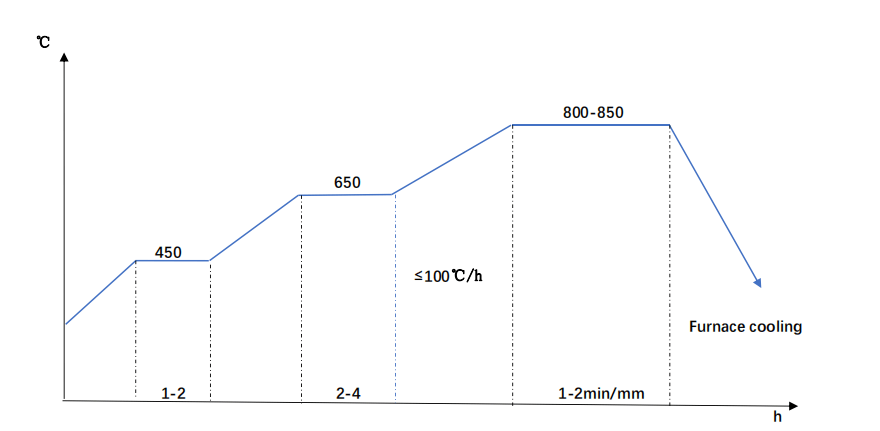

3.Heat Treatment

- Normalizing:860℃-880℃,Cool in air

- Soft Annealing:650℃-680℃,Cool in furnace,max. 248 HB

- Full Annealing:800-850℃,Cool in furnace

- Hardening:830 – 860°C,oil quench is recommended

- Tempering:540°C – 660°C, cool in still air

34CrNiMo6 Normalizing Diagram

34CrNiMo6 Annealing Diagram

4.Mechanical Property with Quenched and Tempered condition as per EN10083

| Size,mm | Tensile,Mpa | Yield,Mpa | Elongation,% | Reduction,% | Charpy Impact,J |

| ≤16 | 1200-1400 | ≥1000 | ≥9 | ≥40 | - |

| 16-40 | 1100-1300 | ≥900 | ≥10 | ≥45 | ≥45 |

| 40-100 | 1000-1200 | ≥800 | ≥11 | ≥50 | ≥45 |

| 100-160 | 900-1100 | ≥700 | ≥12 | ≥55 | ≥45 |

| 160-250 | 800-950 | ≥600 | ≥13 | ≥55 | ≥45 |

5.Mechanical Property with Quenched and Tempered condition as per EN10250

| Thickness,mm | Tensile,Mpa | Yield,Mpa | Elongation,% | Charpy Impact,J |

| ≤160 | ≥800 | ≥600 |

L:≥13 T:≥9 |

L:≥45 T:≥22 |

| 160-330 | ≥750 | ≥540 |

L:≥14 T:≥10 |

L:≥45 T:≥22 |

| 330-660 | ≥700 | ≥490 |

L:≥15 T:≥11 |

L:≥40 T:≥20 |

6.Mechanical Property of Testing Data for Quenched and Tempered condition

| Size mm |

Tensile,Mpa |

Yield,Mpa |

Elongation,% |

Reduction,% |

Charpy Impact,J |

Hardness,HB |

| Φ200 | 925 | 740 | 18 | 61.5 | 104/108/118 | 302-323 |

| Φ280 | 925 | 740 | 18 | 63.5 | 106/103/101 | 286-309 |

| Φ350 | 905 | 725 | 20 | 64.5 | 112/110/111 | 288-312 |

| Φ430 | 825 | 650 | 17.4 | 54.5 | 89/105/113 | 270-275 |

| Φ575 | 785 | 590 | 20 | 50 | 97/91/76 | 270-272 |

7.Supply Size & Condition

- Round Bars: Dia.80 – 1,000mm as Forged

- Flat / Square Bars: Thickness Max.800mm

- Shafts, Rollers, Blocks: Customized or According to Drawing

- Rolled Round Bars: Dia.16 – 250mm with UT Assurance

Heat treatment:Quenched and Tempered (+QT), Normalizing (+N), Annealing (+A)

Surface finish:Black / Rough turned / Peeled